Blogs

The Importance of Noise Studies in FEED and EPC Phases

In industrial projects, particularly within sectors like oil and gas, petrochemicals, and power generation, managing environmental and occupational noise is a critical aspect of project planning and execution. Conducting comprehensive noise studies during the Front-End Engineering Design (FEED) and Engineering, Procurement, and Construction (EPC) phases is essential to ensure regulatory compliance, protect worker health, and maintain community relations.

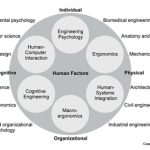

Understanding Noise Studies

Noise studies involve the assessment and analysis of sound levels associated with industrial operations. These studies aim to:

- Establish Baseline Noise Levels: Conduct surveys to determine existing ambient noise conditions.

- Predict Future Noise Emissions: Use modelling tools to forecast noise levels from proposed equipment and activities.

- Develop Mitigation Strategies: Identify measures to minimize noise impact, such as equipment selection, layout optimization, and installation of noise barriers.

Integration During FEED Phase

In the FEED phase, noise studies are integrated to:

- Inform Design Decisions: Influence the selection and placement of equipment to minimize noise propagation.

- Ensure Regulatory Compliance: Align project designs with local and international noise regulations and standards.

- Facilitate Stakeholder Engagement: Provide data to address community concerns regarding potential noise pollution.

Application in EPC Phase

During the EPC phase, the focus shifts to:

- Implement Mitigation Measures: Actualize the noise control strategies developed during FEED.

- Monitor and Verify: Conduct on-site measurements to ensure noise levels remain within acceptable limits.

- Adapt and Manage: Adjust operations and controls in response to monitoring data to maintain compliance and minimize impact.