Blogs

Home / Blogs

The Critical Value of CTOD: Understanding Fracture Mechanics

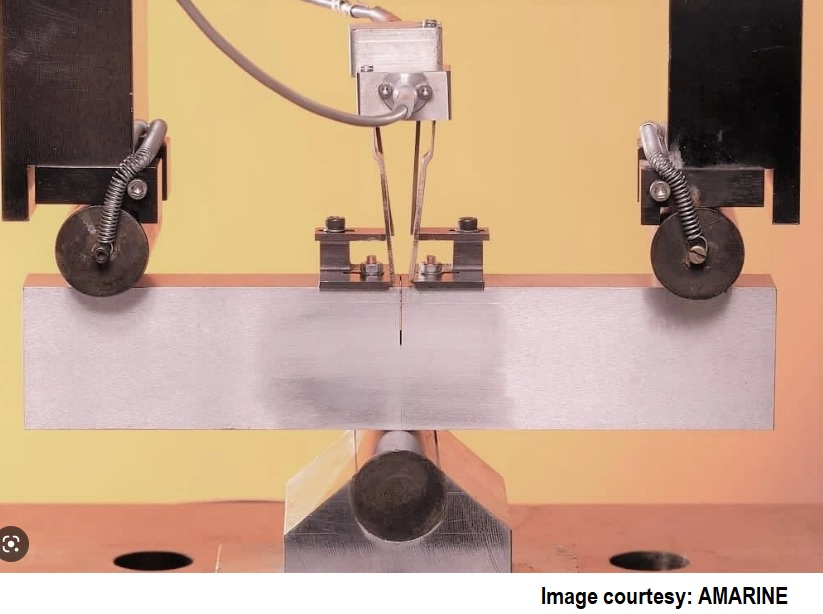

Crack Tip Opening Displacement (CTOD) is a significant parameter in the field of fracture mechanics, which focuses on the study of the behaviour of materials and structures under stress. CTOD is used to characterize the resistance of a material to fracture, providing a basis for evaluating the performance and lifespan of materials and structures.

- Significance of Critical CTOD in Fracture Mechanics

- Material Selection: The critical CTOD value plays a crucial role in material selection for various applications. By comparing the CTODc values of different materials, engineers can determine the most suitable material for specific applications, ensuring better performance and longer service life.

- Structural Integrity Assessment: CTODc is used to assess the structural integrity of components and structures subjected to stress. It provides a quantitative measure to evaluate the risk of crack growth and failure. By determining the CTODc value of a material, engineers can establish safety margins and implement appropriate maintenance practices to prevent catastrophic failure.

- Failure Analysis: In the event of a structural failure, the critical CTOD value can help identify the root cause of the failure. By examining the CTODc value in relation to the material and environmental factors, engineers can pinpoint the factors contributing to the failure and implement corrective measures.

- Design Optimization: CTODc is an essential parameter in the design optimization process. Understanding the critical value of CTOD helps engineers to optimize the design of components and structures to minimize the risk of fracture and ensure long-term performance.

- Applications of Critical CTOD in Various Industries

- Aerospace: The critical CTOD value is of paramount importance in the aerospace industry, where materials must withstand extreme stress and temperatures. CTODc is used to evaluate the performance of materials for aircraft components and ensure the structural integrity of the aircraft.

- Oil and Gas: In the oil and gas industry, CTODc is used to assess the performance of pipeline materials under stress, ensuring safe and efficient transportation of oil and gas over long distances.

- Automotive: The automotive industry relies on CTODc values to optimize the design of vehicle components, minimize the risk of fracture, and improve vehicle performance and safety.

- Infrastructure: In the construction industry, CTODc is used to evaluate the performance of materials used in bridges, buildings, and other infrastructure, ensuring long-term structural integrity and safety.

- Typical Critical CTOD Values

- Brittle materials, such as ceramics and some hard polymers, typically exhibit low critical CTOD values. These materials are more susceptible to crack propagation and fracture under stress, as they do not exhibit significant plastic deformation.

- Ductile materials, like metals and alloys, generally have higher critical CTOD values due to their ability to undergo plastic deformation. Materials such as steel, aluminium, and titanium alloys used in aerospace, automotive, and construction applications often exhibit CTOD values in the range of 0.1 to 10 mm, depending on factors like composition, microstructure, and heat treatment.

- Toughened materials, such as fibre-reinforced composites, can display a wide range of critical CTOD values, depending on factors like the fibre type, matrix material, and interface bonding between the fibres and the matrix. Some fibre-reinforced composites may have critical CTOD values comparable to ductile metals and alloys.

Conclusion

The critical value of Crack Tip Opening Displacement (CTOD) is an essential parameter in fracture mechanics, providing valuable insight into the fracture resistance of materials and structures. Understanding the critical CTOD value is crucial for material selection, structural integrity assessment, failure analysis, and design optimization across various industries. By leveraging this parameter, engineers can minimize the risk of fracture and ensure the long-term performance and safety of materials and structures. By focusing on the critical CTOD value, industries can not only improve the reliability and durability of their products but also contribute to the overall safety and well-being of end-users. As advancements in materials science and engineering continue, the critical CTOD value will remain a key factor in the development and evaluation of innovative materials and applications.

Anil K Vashishta

Anil K Vashishta is a Metallurgical Engineer from the National Institute of Technology, Rourkela, with over 29 years of expertise in materials, corrosion, and metallurgical/mechanical laboratory management. As the Managing Director of Colossal Consultants LLC in the United Arab Emirates—founded in 2019 to serve the GCC and South-Eastern regions—Anil applies his extensive background to support diverse industries, particularly oil and gas.

A Certified NACE Corrosion Specialist and NACE Material Selection Design Specialist, Anil specializes in corrosion assessment and mitigation, material selection, turnkey laboratory setup, and root cause/failure analysis. His comprehensive skills also include in-situ replica metallography, condition assessment, coating evaluations, and cathodic protection. With a deep passion for technical excellence and practical solutions, Anil continues to drive innovation and best practices in the field of materials engineering.

In this article

No posts found