Blogs

Home / Blogs

Remaining Life Assessment

- Data collection: Gather historical data on the asset, including information on its design, construction, operating conditions, maintenance history, and any past incidents or failures.

- Inspection and testing: Perform non-destructive testing (NDT) and other inspection techniques to assess the current condition of the asset, identify any signs of degradation or damage, and gather additional data.

- Condition assessment: Analyze the data collected during inspections and testing, along with historical data, to determine the current condition of the asset and identify any trends in degradation or failure.

- Failure analysis: Study the potential failure modes and consequences, and determine the likelihood and potential impact of each failure mode on the asset’s performance, safety, and environmental impact.

- Remaining life estimation: Based on the asset’s current condition, past performance, and anticipated future operating conditions, estimate the remaining service life of the asset. This involves the use of mathematical models, engineering analysis, and expert judgment.

- Recommendations: Based on the RLA results, develop recommendations for maintenance, repair, or replacement strategies, along with associated costs and benefits. This information can be used to make informed decisions about asset management and investment.

Anil K Vashishta

Anil K Vashishta is a Metallurgical Engineer from the National Institute of Technology, Rourkela, with over 29 years of expertise in materials, corrosion, and metallurgical/mechanical laboratory management. As the Managing Director of Colossal Consultants LLC in the United Arab Emirates—founded in 2019 to serve the GCC and South-Eastern regions—Anil applies his extensive background to support diverse industries, particularly oil and gas.

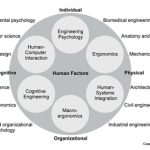

A Certified NACE Corrosion Specialist and NACE Material Selection Design Specialist, Anil specializes in corrosion assessment and mitigation, material selection, turnkey laboratory setup, and root cause/failure analysis. His comprehensive skills also include in-situ replica metallography, condition assessment, coating evaluations, and cathodic protection. With a deep passion for technical excellence and practical solutions, Anil continues to drive innovation and best practices in the field of materials engineering.

In this article

No posts found