Blogs

Home / Blogs

Layer of Protection Analysis (LOPA)

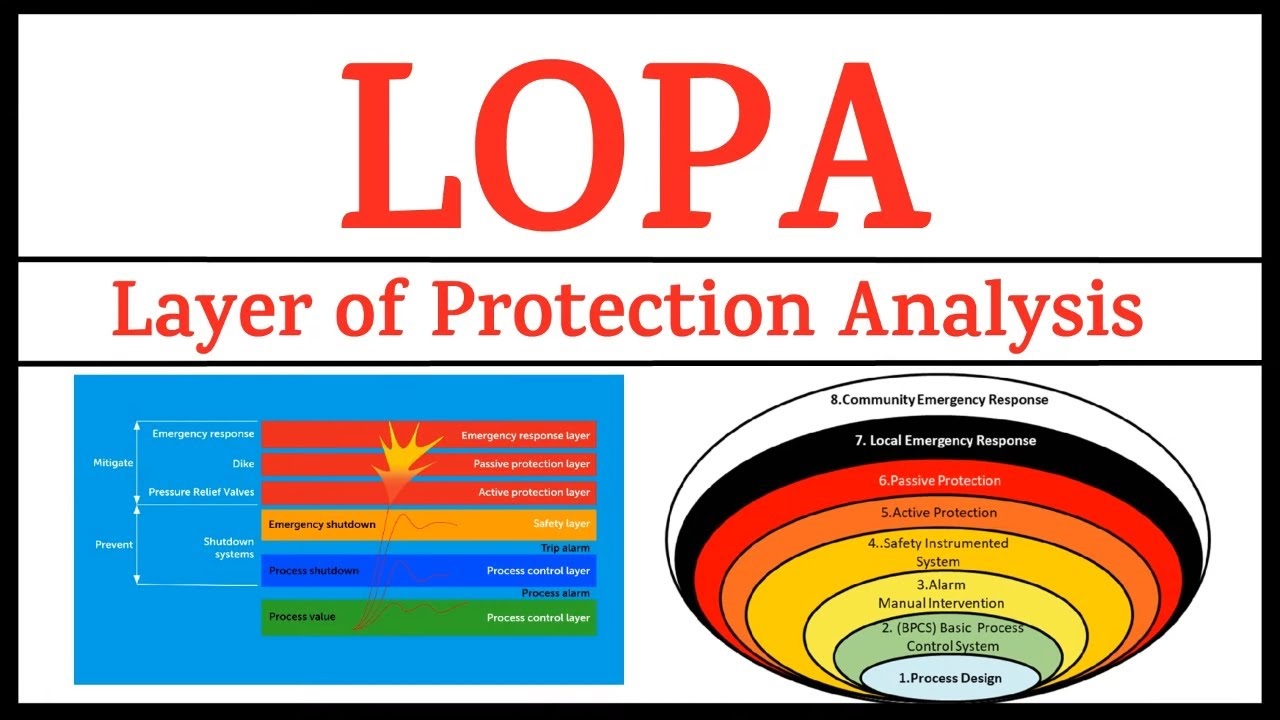

Layers of Protection Analysis (LOPA) is a structured and systematic approach for evaluating the effectiveness of safety systems. It is a semi-quantitative risk assessment methodology used primarily in the process industries, such as chemical, petrochemical, and oil and gas sectors. It is an intermediate approach between a qualitative hazard analysis, like Hazard and Operability Study (HAZOP), and a fully quantitative risk analysis, like Quantitative Risk Assessment (QRA).

The primary objective of LOPA is to evaluate the adequacy and effectiveness of independent protection layers (IPLs) in a process facility to minimize the risk associated with identified hazardous scenarios. IPLs can be safety instrumented systems (SIS), pressure relief devices, process alarms, safety interlocks, and other safety measures designed to prevent or mitigate the consequences of an unwanted event.

LOPA involves the following steps:

- Identifying hazardous scenarios: Using qualitative hazard analysis techniques, like HAZOP or What-If Analysis, potential hazardous scenarios are identified.

- Estimating the initiating event frequency: The frequency at which the initiating event for a hazardous scenario may occur is estimated based on historical data, expert judgment, or industry guidelines.

- Identifying and evaluating IPLs: Independent protection layers are identified and assessed for their effectiveness in preventing or mitigating the consequences of the hazardous scenario. Each IPL is assigned a risk reduction factor (RRF) based on its reliability, effectiveness, and independence.

- Calculating the residual risk: The residual risk associated with a hazardous scenario is calculated by multiplying the initiating event frequency by the product of the failure probabilities of all identified IPLs. The residual risk is then compared to the tolerable risk criteria defined by the organization or regulatory authorities.

- Risk management decision-making: If the residual risk is found to be higher than the tolerable risk, additional IPLs or risk reduction measures may be proposed to reduce the risk to an acceptable level.

Anil K Vashishta

Anil K Vashishta is a Metallurgical Engineer from the National Institute of Technology, Rourkela, with over 29 years of expertise in materials, corrosion, and metallurgical/mechanical laboratory management. As the Managing Director of Colossal Consultants LLC in the United Arab Emirates—founded in 2019 to serve the GCC and South-Eastern regions—Anil applies his extensive background to support diverse industries, particularly oil and gas.

A Certified NACE Corrosion Specialist and NACE Material Selection Design Specialist, Anil specializes in corrosion assessment and mitigation, material selection, turnkey laboratory setup, and root cause/failure analysis. His comprehensive skills also include in-situ replica metallography, condition assessment, coating evaluations, and cathodic protection. With a deep passion for technical excellence and practical solutions, Anil continues to drive innovation and best practices in the field of materials engineering.

In this article

No posts found