Blogs

HIC, SSCC and SOHIC

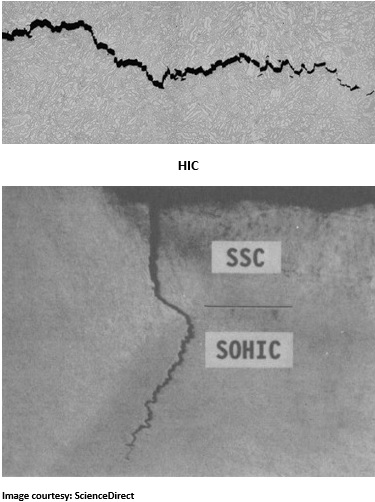

Hydrogen absorbed during production, operations, or exposure to corrosive environments containing H2S

Hydrogen atoms migrate to regions of high stress, combine to form molecular hydrogen, and create pressure, leading to cracks

Random, stepwise pattern, typically in the direction of the metal’s rolling plane

Typically affects the metal at or near the mid-thickness, following the rolling plane

Proper material selection, controlling H2S levels, using low hydrogen welding techniques, and applying coatings or inhibitors

Exposure to sour environments containing H2S; the presence of sulfides in the steel microstructure

Corrosive hydrogen atoms react with metal sulfides, leading to the formation of cracks under the influence of applied or residual stress

Can be intergranular or transgranular, but often propagate in the direction of applied or residual stress

Can affect any part of the metal’s microstructure

Material selection, controlling H2S levels, using low hydrogen welding techniques, stress relief heat treatment, and applying coatings or inhibitors

A combination of hydrogen absorption and stress, often in H2S-containing environments

Hydrogen atoms collect along the planes of residual or applied stress, resulting in the development of cracks oriented parallel to the stress direction

Cracks are oriented parallel to the direction of applied or residual stress, often forming multiple crack layers

Primarily affects the mid-thickness of the metal, similar to HIC, but can propagate deeper through the material

Material selection, controlling H2S levels, using low hydrogen welding techniques, stress relief heat treatment, and applying coatings or inhibitors