Blogs

Elevated temperature Creep test of Metallic Material

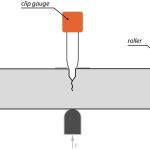

ASTM E139 is a standard method for performing elevated temperature creep testing of metallic materials under constant strain rate conditions. This procedure involves subjecting a cylindrical specimen to a constant tensile load at a specified temperature for several hours to several days, depending on the material and application. The deformation of the specimen is continuously measured using an extensometer, and the resulting data is used to determine the material’s creep properties, such as creep rate, creep strain, and time to failure, under constant loading conditions.

The main objective of the test is to evaluate the creep behaviour of metallic materials at elevated temperatures and to determine their time-dependent deformation characteristics. The test results can be used to design and select materials for high-temperature applications, as well as to develop more accurate predictive models for the long-term behaviour of metallic materials under stress.

The ASTM E139 standard provides guidelines for conducting the elevated temperature creep test, including specimen preparation, testing equipment, and data analysis. It also outlines the reporting requirements for test results, such as stress and strain data, test duration, and temperature. By following this standard, the consistency and reproducibility of test results can be ensured, allowing for meaningful comparisons between different materials and testing conditions.