Blogs

Home / Blogs

Feasibility Studies - Laboratory Setup

A feasibility study report for setting up a third-party independent Material/Metallurgical testing laboratory should include the following contents:

- Executive Summary: A brief overview of the entire feasibility study, highlighting the main points and conclusions.

- Introduction: A description of the study’s purpose and objectives, the project’s scope, and a brief introduction to the Material/Metallurgical testing industry.

- Market Analysis: An in-depth assessment of the market potential, including:

- Target customer segments and industries served: Identification of the key customer groups and industries that could benefit from the testing services.

- Competitor analysis: Overview of competitors, including their services, strengths, and weaknesses.

- Market trends, growth projections, and potential opportunities: Analysis of current trends, market growth expectations, and emerging opportunities in the sector.

- Technical Feasibility: A detailed analysis of the technical aspects of the laboratory, such as:

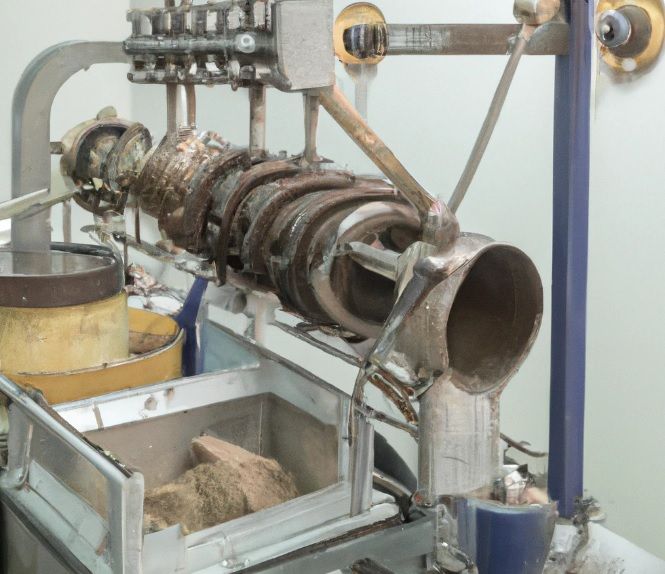

- Required testing equipment and instruments: Identification of the necessary tools and machinery for laboratory operations.

- Space and infrastructure requirements: Assessment of the space, layout, and infrastructure needs for the lab.

- Quality and safety standards: Overview of the required quality standards and safety protocols.

- Laboratory accreditation and certification requirements: Identification of relevant certifications and standards for laboratory operation.

- Technological advancements and innovations in the industry: Consideration of current technological trends and innovations that may impact the laboratory.

- Operational Feasibility: An examination of the operational aspects, including:

- Staffing requirements: Including qualifications, experience, and training for laboratory personnel.

- Laboratory management systems and procedures: Overview of the systems and procedures required to manage operations.

- Workflow and process optimization: Identifying ways to streamline processes and improve efficiency.

- Supply chain management: For consumables and equipment maintenance.

- Risk assessment and mitigation strategies: Identifying potential risks and ways to mitigate them.

- Financial Feasibility: A thorough financial analysis, covering:

- Initial capital investment: For equipment, infrastructure, and setup costs.

- Operating expenses: Including salaries, utilities, consumables, and maintenance.

- Projected revenue streams: Including pricing strategies and revenue growth potential.

- Break-even analysis and profitability projections: Calculating the point at which the lab becomes profitable.

- Financial risk assessment and sensitivity analysis: Identifying potential financial risks and analyzing their impact.

- Legal and Regulatory Compliance: A review of the legal and regulatory requirements for setting up and operating a material/metallurgical testing laboratory, including:

- Business registration and licensing requirements: Necessary steps for legal establishment.

- Environmental and safety regulations: Ensuring compliance with laws to protect the environment and lab workers.

- Industry-specific standards and certifications: Relevant regulations specific to material/metallurgical testing.

- Intellectual property protection: If applicable, safeguarding the lab’s innovations.

- Data privacy and security regulations: Ensuring protection of confidential data.

- SWOT Analysis: A comprehensive assessment of the project’s strengths, weaknesses, opportunities, and threats, taking into account the internal and external factors affecting the success of the laboratory.

- Implementation Plan: A step-by-step roadmap outlining the tasks, milestones, and timelines for setting up the laboratory, including a risk management plan to address potential obstacles and challenges.

- Conclusion and Recommendations: A summary of the findings, insights from the feasibility study, and recommendations on whether to proceed with the project or consider alternative options.

Anil K Vashishta

Anil K Vashishta is a Metallurgical Engineer from the National Institute of Technology, Rourkela, with over 29 years of expertise in materials, corrosion, and metallurgical/mechanical laboratory management. As the Managing Director of Colossal Consultants LLC in the United Arab Emirates—founded in 2019 to serve the GCC and South-Eastern regions—Anil applies his extensive background to support diverse industries, particularly oil and gas.

A Certified NACE Corrosion Specialist and NACE Material Selection Design Specialist, Anil specializes in corrosion assessment and mitigation, material selection, turnkey laboratory setup, and root cause/failure analysis. His comprehensive skills also include in-situ replica metallography, condition assessment, coating evaluations, and cathodic protection. With a deep passion for technical excellence and practical solutions, Anil continues to drive innovation and best practices in the field of materials engineering.

In this article

No posts found