CFD & FEA

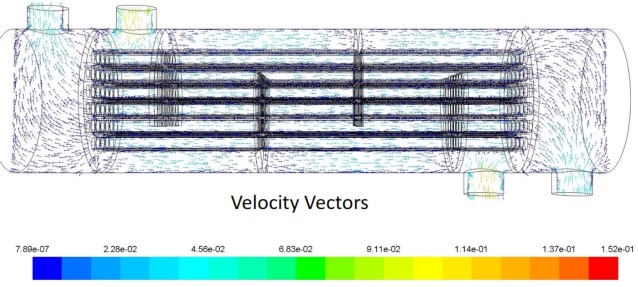

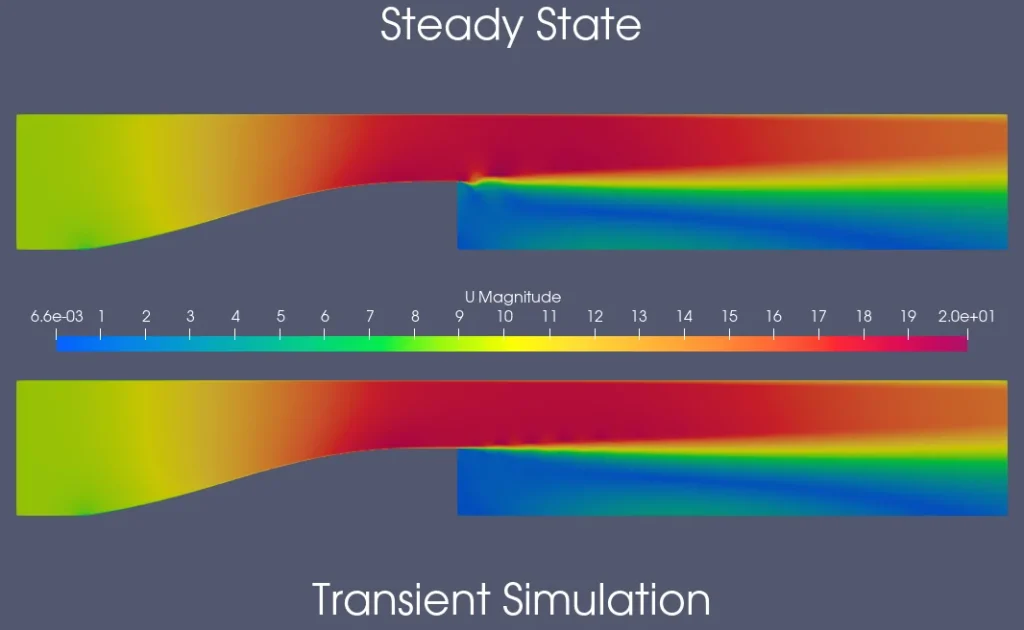

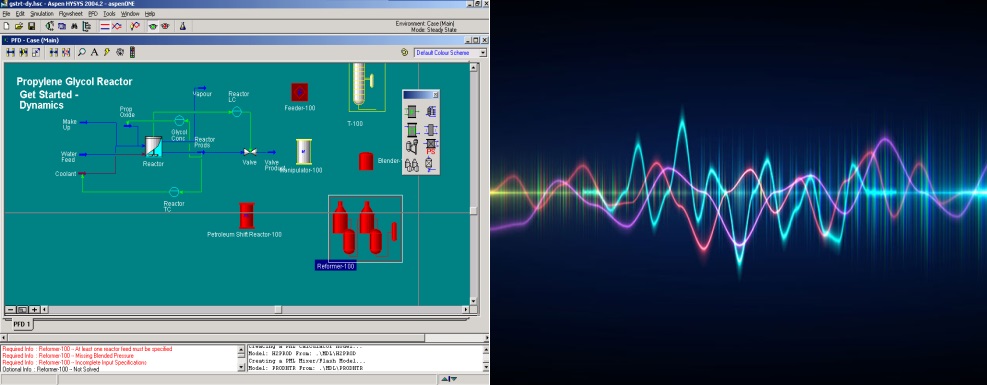

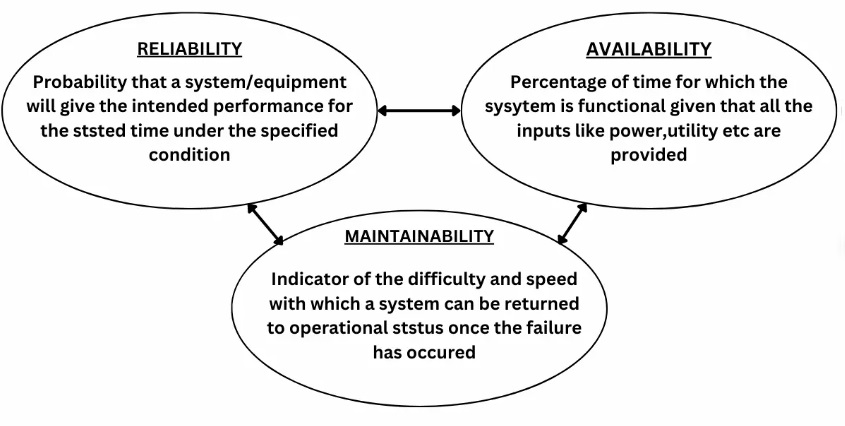

CFD & FEA Cfd & Fea Computational Fluid Dynamics (CFD Modelling) Computational Fluid Dynamics (CFD Modelling) is the process of mathematically modelling a physical phenomenon involving fluid flow and solving it numerically using computational techniques. Typical software used for CFD Modelling is ANSYS-Fluent, SoundPLAN, THERM-2D or Star CCM+. Laminar (blood → oil) and turbulent (atmospheric → aerodynamics) flow analysis Steady and Transient analysis Single-phase and Multi-phase (Gas-Liquid/ Gas-Solid/ LiquidLiquid) flow analysis Newtonian (water, air, glycerol) and Non-Newtonian (blood, crude oil) flow analysis Aeroacoustics analysis (fluid and mechanical) Granular-fluid systems (Pneumatic conveyors, Fluidized bed reactors) Heating, cooling, and mass transfer analyses Reaction modeling including combustion Finite Element Analysis (FEA) Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. Typical software used for FEA are ABAQUS or Tosca or Fe-safe. • Linear and non-linear stress analyses• Dynamic/explicit vibration, buckling, blast & crash analyses• Contact modelling (welded, bolted, and threaded connections)• Steady-state and transient thermal analysis• Advanced material modelling• Multiphysics capabilities (fluid structure, fluid thermal, and coupled thermal structural)• Welding engineering analysis• Structural optimization• Failure/fracture and fatigue cyclic loading analysis• Product development – virtual testing and validation Asset Integrity CFD & FEA STEADY AND TRANSIENT FLOW SIMULATION STUDIES VIBRATION, HYSYS SIMULATION AND NOISE STUDIES RELIABILITY, AVAILABILITY AND MAINTAINABILITY (RAM) STUDIES RISK BASED INSPECTION (RBI) FITNESS FOR SERVICE AND REMAINING LIFE ASSESSMENT Send enquiry