Blogs

Human Factors Engineering: Designing Workplaces for People

We often hear about the importance of well-designed technology or innovative processes. But what about the people who actually use these tools and navigate these workflows every single day? This is where Human Factors Engineering (HFE) plays a vital role.

At its core, HFE is about understanding how humans interact with systems and then applying this knowledge to design better, safer, and more efficient work environments. It recognizes that people have limitations in their physical and cognitive abilities and that ignoring these limitations can lead to errors, accidents, reduced productivity, and even safety risks.

What Does HFE Encompass?

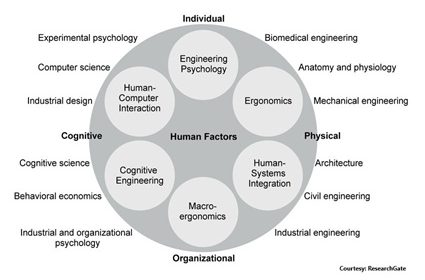

HFE is not just about making things “comfortable,” though that can certainly be a benefit. It’s a multidisciplinary field that considers a wide range of factors:

Physical Ergonomics: This focuses on things like posture, reach, strength, and the design of tools and workstations to minimize physical strain. Think adjustable chairs, well-placed controls, and lifting equipment that prevents injuries.

Cognitive Ergonomics: This addresses the mental workload involved in tasks. It’s about presenting information clearly, designing user-friendly interfaces, and reducing the potential for errors due to confusion or information overload.

Organizational Ergonomics: This involves the overall structure of the work environment, including teamwork, communication, and work schedules. A well-designed work environment includes provisions for suitable accommodations for various tasks.

Environmental Considerations: This includes the effects of noise, lighting, vibration and temperature and how the workspace can be adjusted to be as comfortable and as efficient as possible.

Why Is HFE So Important?

The benefits of incorporating HFE principles are far-reaching:

Enhanced Safety: Reducing the likelihood of human error directly translates to a safer work environment. Well-designed escape routes, clear warnings, and easily accessible safety equipment are crucial.

Improved Efficiency: When systems are designed to match human capabilities, workers can perform their tasks more quickly, accurately, and with less effort.

Reduced Strain and Injuries: Proper ergonomics reduce the risk of musculoskeletal disorders and other injuries, leading to lower healthcare costs and improved employee well-being.

Increased Productivity: A comfortable, safe, and well-organized workplace boosts morale and allows workers to focus on their tasks, leading to higher overall productivity.

Better Overall Performance: By prioritizing the human element, HFE helps create a more effective and reliable system, leading to better operational performance.

Key Principles in Action

What does HFE look like in practice? Consider these examples:

Clear visibility of displays and controls for optimal operational awareness

Clear and Consistent Signage: Ensuring that all signage is easy to read, understand, and located in appropriate locations.

Accessible and Ergonomic Workstations: Providing adjustable workstations, chairs, and equipment that accommodate a diverse workforce.

Optimized Control Placement: Arranging controls in a logical order and within easy reach of the operator.

Well-Designed Emergency Systems: Ensuring that alarms and escape routes are clear, easily accessible, and free of obstructions.

These are just a few examples, but they illustrate the fundamental principle of HFE: designing systems with the end-user in mind. This may range from ensuring proper lighting to prevent eye strain, providing easy access for those using ladders and also ensuring that those controls are located within appropriate reach.

Making a Difference Through HFE

HFE is not a luxury – it’s a necessity for organizations committed to safety, efficiency, and employee well-being. Whether it’s designing a control room, setting up a manufacturing line, or even creating a user-friendly software interface, HFE principles can be applied to create a more effective and human-centered work environment. The end result is a workplace that supports its employees, minimizes risks, and maximizes performance.