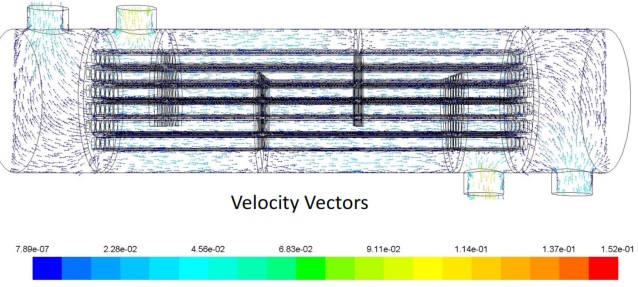

Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. Typical software used for FEA are ABAQUS or Tosca or Fe-safe.

• Linear and non-linear stress analyses

• Dynamic/explicit vibration, buckling, blast & crash analyses

• Contact modelling (welded, bolted, and threaded connections)

• Steady-state and transient thermal analysis

• Advanced material modelling

• Multiphysics capabilities (fluid structure, fluid thermal, and coupled thermal structural)

• Welding engineering analysis

• Structural optimization

• Failure/fracture and fatigue cyclic loading analysis

• Product development – virtual testing and validation