Stress Analysis of Piping

STRESS ANALYSIS OF PIPING

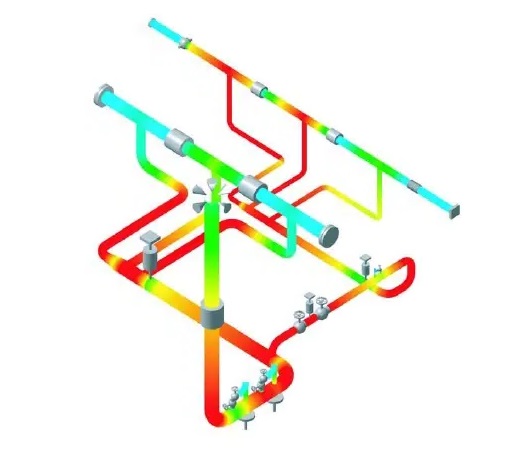

The process of analysing the stress and strain distribution in a piping system under various loading conditions, including pressure, temperature, weight, and external forces, is referred to as piping stress analysis. This analysis is usually conducted using specialized software and encompasses several steps.

- Model Creation: To begin with, an accurate 3D model of the piping system must be generated, encompassing all its components such as pipes, fittings, valves, and supports. The model should precisely depict the actual geometry and arrangement of the piping system.

- Load Analysis: Following the model creation, the loads that affect the piping system, such as pressure, temperature, weight, and external forces like wind, seismic activity, and thermal expansion, must be assessed. These loads are then imposed on the model, and the resulting stresses and strains are computed

- Stress Analysis: Upon establishing the loads, the stress analysis process can commence, which entails determining the stresses and strains in every part of the piping system, including the fittings, supports, and pipes. The resulting stresses and strains are then compared against the allowable values stipulated by the relevant codes and standards.

- Design Review: The outcomes of the stress analysis are evaluated to detect any sections where the stresses or strains surpass the permitted values. To reduce the stresses or strains to acceptable levels, modifications or adjustments to the design may be necessary.

- Documentation: The concluding phase is to record the findings of the stress analysis, encompassing the loads, stresses, and strains, along with any alterations or adjustments made to the design. Usually, this information serves as a point of reference in the future and to showcase compliance with relevant codes and standards.